Table of Contents

ACM Wall Panels Essentials in Utah

In the evolving landscape of Utah construction, ACM wall panels in Utah are gaining traction for their sleek, modern appeal in both residential and commercial projects. Homeowners and builders in Salt Lake City are increasingly turning to these durable solutions to withstand the state’s variable weather, from harsh winters to intense summer heat. Viotell Metal Concepts leads the way with expert fabrication of custom metal wall panels tailored to local architectural styles.

Aluminum composite material, or ACM, features a fire-resistant polyethylene core sandwiched between two thin aluminum sheets, offering a lightweight alternative to heavier solid metal panels–typically weighing just 1.5 pounds per square foot compared to 4-5 pounds for traditional options. This composition ensures ACM panels’ fire resistance meets stringent building codes while providing aesthetic versatility for facades and accents. In Salt Lake City, where low-maintenance exteriors are essential, aluminum composite panels in Utah from Viotell excel in luxury applications, delivering weather-resistant cladding that enhances curb appeal without frequent upkeep. For seamless integration, ACM panels installation in Utah requires precision, which Viotell’s craftsmen handle through custom designs suited to regional demands.

Utah ACM cladding solutions and local aluminum panel systems like these set the foundation for this guide, exploring their technical features, benefits, installation processes, and best practices under Utah conditions. Whether updating a home or elevating a commercial build, connecting with Viotell for a quote in Salt Lake City ensures project success from concept to completion.

Understanding ACM Wall Panels

Aluminum Composite Material (ACM) wall panels offer a modern solution for exterior cladding in Utah, where harsh winters and intense sun demand durable, low-maintenance options. These panels combine aesthetics with functionality, making them ideal for both residential and commercial projects in the region. Understanding their composition, features, and local availability helps builders and homeowners make informed choices that align with Utah’s building codes and climate challenges.

Composition and Materials of ACM Panels

ACM wall panels in Utah consist of a layered structure designed for strength and safety. The core features two thin aluminum sheets bonded to a non-combustible core, typically made from polyethylene or mineral-filled materials to meet fire-rated standards. This setup ensures the panels resist fire propagation, complying with Utah’s stringent building codes for exterior applications.

The aluminum sheets, usually 0.5mm thick, provide a protective outer layer that shields the core from environmental damage. For Utah-specific ACM materials, fire-rated cores like those with aluminum honeycomb are preferred in high-rise or commercial builds to enhance safety during snowy winters and dry summers. Local composite cladding often incorporates UV-stable adhesives, preventing delamination in the state’s variable weather. Imagine sleek panels enhancing the facade of a mountain retreat, offering both beauty and resilience.

Key Features and Specifications

ACM panels stand out for their engineering tailored to demanding environments. Key specifications include standard dimensions up to 5 feet by 20 feet, with a common thickness of 4mm that balances rigidity and ease of handling. Weights typically range from 3.5 to 5 pounds per square foot, making them lighter than many alternatives.

Finishes vary from polyester coatings for basic protection to advanced PVDF for superior color retention and corrosion resistance, crucial for Utah’s sunny exposures. Customization options abound through fabricators in Salt Lake City, such as Viotell, which specializes in tailored aluminum composite panels in Utah for unique project needs.

- Durability: High resistance to weathering, with warranties up to 20 years on finishes.

- Flatness and Rigidity: Maintains shape without warping, ideal for large facades.

- ACM panels installation in Utah: Requires professional crews for precise attachment, often using rivets or clips on subframes.

These attributes ensure long-term performance, transitioning seamlessly to real-world advantages like reduced maintenance in Utah’s climate. When selecting cladding for Utah projects, comparing ACM panels against traditional materials reveals key trade-offs influenced by local conditions like heavy snow loads and solar intensity.

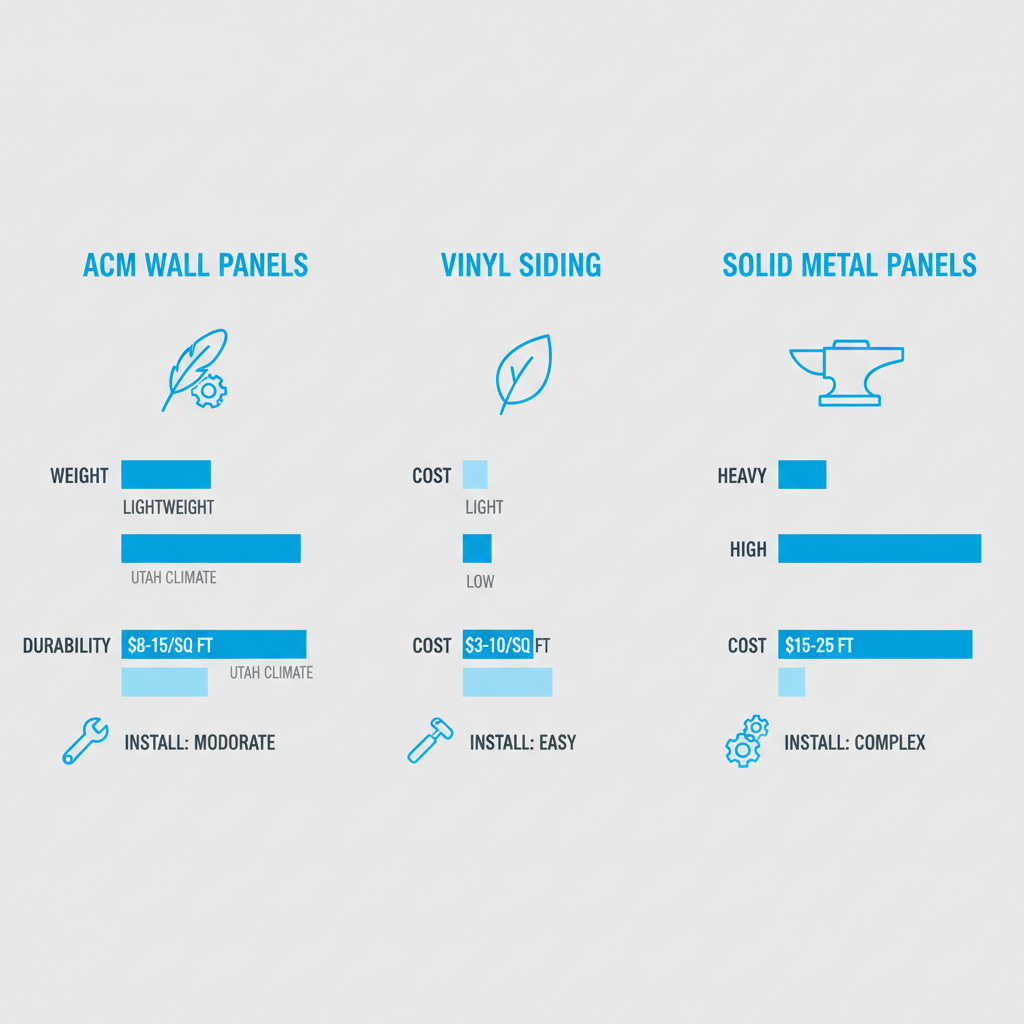

| Material | Weight | Durability in Utah Climate | Cost Range | Installation Ease |

|---|---|---|---|---|

| ACM Panels | Lightweight | High (weather-resistant) | $8-15/sq ft | Moderate |

| Vinyl Siding | Light | Low (fades in sun) | $3-10/sq ft | Easy |

| Solid Metal | Heavy | Very High | $15-25/sq ft | Complex |

This comparison, drawn from industry analyses, highlights ACM’s balanced profile. ACM panels excel in Utah due to their lightweight nature, which simplifies handling during installation on sloped sites, and superior weather resistance that outperforms vinyl’s tendency to fade under intense UV rays. While solid metal offers unmatched strength, its heft increases labor costs–ACM provides a cost-effective middle ground at around $8-15 per square foot locally, promoting easier compliance with building timelines.

Comparison of wall panel options for durable Utah exteriors.

Building on these insights, the visual breakdown underscores how ACM’s specifications translate to practical benefits, such as lower long-term upkeep compared to wood’s vulnerability to moisture in Utah’s alternating freeze-thaw cycles. Homeowners can visualize these options in action, weighing factors like budget and site access for optimal selection.

Availability in Utah Markets

Sourcing aluminum composite panels in Utah is straightforward, especially in Salt Lake City, where suppliers cater to the booming construction scene. Local distributors stock standard and custom options, with prices reflecting regional demand–expect $8-15 per square foot for quality grades.

Top choices include major wholesalers like those partnered with national brands, but for bespoke needs, turn to fabricators in Salt Lake City such as Viotell, known for precision cutting and finishing. These services support luxury builds, integrating panels with complementary elements like Park City metal roofing for cohesive exteriors.

- Suppliers: ABC Supply and local outlets in the Salt Lake Valley offer quick delivery.

- Fabrication Services: Viotell provides routing, bending, and assembly for on-site efficiency.

- Best Options: Fire-rated varieties from ALPOLIC or Reynobond suit high-end Utah projects.

Benefits of ACM Wall Panels

Aluminum composite material (ACM) wall panels offer transformative advantages for building exteriors, particularly in Utah’s demanding climate. Drawing from Viotell’s expertise in Salt Lake City projects, these panels provide unmatched durability, aesthetic versatility, and long-term value. Homeowners and contractors alike appreciate how ACM enhances luxury properties while minimizing ongoing concerns.

Durability and Weather Resistance in Utah

Utah’s harsh winters and intense summers test exterior materials relentlessly. ACM wall panels in Utah stand out for their exceptional resistance to freeze-thaw cycles, heavy snow loads, and high winds common in the region. Composed of two aluminum sheets bonded to a polyethylene core, these panels withstand temperatures from -20°F to 180°F without warping or cracking. In Salt Lake City, where blizzards can dump over 50 inches of snow annually, local panel durability proves vital for maintaining structural integrity.

Consider a recent Viotell installation on a commercial building in downtown Salt Lake City. The panels endured 60 mph gusts during a winter storm with no damage, outperforming traditional options. Key durability benefits include:

- UV resistance: Prevents fading from Utah’s high-altitude sun exposure.

- Impact strength: Resists hail and debris, reducing repair needs.

- Fire safety: Class A rating enhances building code compliance in wildfire-prone areas.

According to Houzz professionals, such features extend lifespan to over 30 years, far surpassing alternatives in Utah cladding advantages. This reliability translates to peace of mind for property owners facing the Wasatch Front’s variable weather.

Aesthetic and Customization Advantages

Beyond functionality, aluminum composite panels in Utah elevate architectural design with unparalleled flexibility. ACM mimics premium metals like zinc or copper, allowing for sleek, modern exteriors that blend seamlessly with Utah’s diverse landscapes. Custom colors, textures, and finishes enable architects to create striking facades, from matte blacks for urban lofts to wood-grain effects for rustic retreats.

In luxury builds, such as a Park City luxury home transformed by Viotell, ACM panels integrated bold metallic accents with stone elements, achieving a high-end look at a fraction of solid metal costs. Houzz exterior pros highlight how these panels support curved or angled installations, ideal for contemporary Utah architecture. Customization perks encompass:

- Color options: Over 100 choices, including anodized finishes for longevity.

- Easy integration: Pairs with windows, doors, and roofing for cohesive designs.

- Energy efficiency: Reflective surfaces reduce heat gain, lowering cooling costs in summer.

This versatility not only boosts curb appeal but also increases property values, making ACM a favorite for upscale residential and commercial projects across the state.

| Benefit Category | ACM Panels | Traditional Wood | Vinyl |

|---|---|---|---|

| Durability (Years) | 30+ | 15-20 | 10-15 |

| Maintenance Cost | Low | High (painting) | Medium (fading) |

| Aesthetic Versatility | High (custom finishes) | Natural but limited | Basic colors |

Cost-Effectiveness and Maintenance

Investing in ACM panels installation in Utah yields significant returns through upfront affordability and sustained savings. Installed at $8-15 per square foot, including labor, ACM undercuts premium metals while offering comparable performance. With a 30+ year lifespan, owners recoup costs via reduced replacements and energy bills–up to 20% lower heating demands in insulated setups.

Viotell’s Salt Lake City projects demonstrate ROI: A luxury condo facade saved $50,000 over 10 years versus wood cladding, factoring in maintenance alone. Low upkeep is a hallmark; panels require only occasional cleaning with mild soap, no painting or sealing needed. Honest note: Initial costs may seem higher than vinyl, but long-term value prevails in Utah’s economy. For comprehensive exterior care, watch for roof inspection signs to ensure panels integrate with overall building health. Economic advantages include:

- Quick installation: Reduces labor time by 30%.

- Warranty coverage: Up to 25 years against delamination.

- Resale boost: Enhances marketability for Utah properties.

How ACM Wall Panels Work

Aluminum composite material (ACM) wall panels offer a lightweight, durable cladding solution ideal for Utah’s varied climate. These panels consist of two aluminum sheets bonded to a non-combustible core, providing excellent weather resistance and aesthetic appeal. In regions like Salt Lake City, where high winds and temperature fluctuations are common, proper installation ensures longevity and structural integrity. This section breaks down the process, tools, and local adaptations, drawing on expertise from companies like Viotell for seamless execution.

Installation Process Overview

The installation of ACM wall panels in Utah begins with thorough site preparation to address local challenges such as seismic activity and altitude effects. First, inspect the building frame for levelness and compliance with Utah building codes, clearing debris and applying a weather-resistant barrier. Next, measure and cut panels using precise dimensions tailored to the structure’s contours, accounting for thermal expansion in extreme temperatures.

Third, position the panels against the subframing, securing them with clips or rivets spaced every 12-16 inches for stability. Seal joints with high-performance caulk to prevent moisture ingress, especially crucial in Utah’s dry yet snowy conditions. Finally, inspect the entire facade for alignment and apply any finishing touches. This step-by-step approach typically costs $10-20 per square foot in Utah, including labor from certified installers. For complex jobs, consult professionals versed in ACM panels installation in Utah to avoid common pitfalls like uneven fastening.

Step-by-step guide to ACM wall panel installation process.

Tools and Techniques Required

Installing aluminum composite panels in Utah requires specialized tools to handle their lightweight yet rigid nature. Essential equipment includes metal shears for clean cuts, cordless drills for riveting, and laser levels for precise alignment–tools that differ from those used for heavier solid metal panels. Rivet guns and clip applicators facilitate quick attachment, reducing labor time compared to welding solid metals.

Professional techniques emphasize dry-gasket systems over wet sealants for flexibility in Utah’s thermal swings. For instance, engage clips allow panels to expand and contract without stress, a key difference from rigid solid panel methods that risk cracking. In Salt Lake City, pros recommend torque-controlled riveting to meet wind load standards.

Integration with Utah Structures

ACM panels integrate seamlessly with Utah’s residential and commercial frames, attaching via aluminum subgirders or Z-clips to wood or steel substrates. In seismic-prone areas, flexible fasteners absorb movement, ensuring compliance with local codes. For Salt Lake City high-rises, panels clip onto curtain wall systems, providing insulation against altitude-driven winds.

Local installation methods adapt to weather by incorporating expansion joints every 20 feet, preventing buckling in freeze-thaw cycles. Residential applications on homes near Park City use ACM for accents, blending with Park City roofing guide principles for cohesive exteriors. Commercial builds benefit from ACM’s fire-rated cores, attaching directly to insulated backings for energy efficiency. Costs align at $10-20 per square foot, with tips like pre-drilling for high-altitude installs to avoid material warping.

Best Practices for ACM Wall Panels

Implementing ACM wall panels effectively requires careful attention to local conditions in Utah, where harsh winters and high winds can impact performance. These best practices ensure durability, compliance, and aesthetic appeal for both residential and commercial projects. By focusing on preparation, maintenance, and professional expertise, property owners can maximize the benefits of these modern cladding solutions while minimizing risks.

Preparation and Planning in Utah

Proper preparation is essential for successful ACM wall panel installations, especially in the variable climate of Salt Lake City areas. Begin with a thorough site assessment to evaluate structural integrity, wind loads, and exposure to elements like snow accumulation. Utah’s building codes demand specific permitting processes; consult local authorities early to avoid delays.

Key steps include:

- Selecting materials suited to Utah’s environment, such as UV-resistant finishes to combat intense sunlight.

- Incorporating wind-resistant fastening systems, as per guidelines for high-wind zones.

- Planning for snow-prone roofs by integrating protective features.

Maintenance and Longevity Tips

Ongoing care is crucial for preserving the sleek appearance and functionality of aluminum composite panels in Utah. Utah panel care routines should account for dust from arid conditions and corrosive effects of winter snow and salt.

- Cleaning panels twice yearly with mild soap and water to remove dust buildup.

- Inspecting and resealing joints before winter to protect against freeze-thaw cycles.

- Using heat cable systems in snow-vulnerable areas to prevent ice dams.

Choosing Local Professionals

Selecting experienced fabricators and installers is vital for high-quality ACM panels installation in Utah. Look for companies with certifications from organizations like AAMA, ensuring adherence to industry standards for fabrication and erection. Viotell Metal Concepts exemplifies a trusted local provider, offering specialized services for ACM installations with a focus on precision and durability.

Choosing ACM Wall Panels in Utah

When selecting ACM wall panels in Utah, it’s essential to consider their core features that make them ideal for the region’s diverse climate, from snowy winters to hot summers. These panels offer exceptional durability, weather resistance, and aesthetic versatility, ensuring structures stand strong against Utah’s harsh elements. The benefits of aluminum composite panels in Utah extend to their longevity and low maintenance, often lasting 30 to 50 years with minimal upkeep. For Utah ACM solutions overview in your local panel wrap-up, connect with experts like Viotell in Salt Lake City. While enhancing your walls, also watch for roof damage signs to maintain overall property integrity.