Table of Contents

Exploring Custom Metal Fabrication in Utah

In the heart of Utah’s dynamic construction scene, custom metal fabrication in Utah stands out as a cornerstone for luxury residential and commercial projects. Viotell Metal Concepts, based in Salt Lake City, leads the way with precision craftsmanship tailored to the region’s unique needs. From architectural elements like architectural metal roofing Utah to intricate wall panels, these services transform visionary designs into durable realities amid Utah’s varied climate, including heavy snow in the mountains and urban growth in the valleys.

Custom metal fabrication involves creating bespoke components through essential techniques such as cutting, bending, and welding, as outlined in standard steel fabrication processes. Viotell specializes in metal fabrication in Utah, focusing on high-end applications like sheet metal fabrication in Utah for roofing systems and ornamental work. Using locally compliant materials that withstand snow loads and temperature swings, this tailored metalwork services in Utah ensures longevity and aesthetic appeal for Salt Lake City’s booming luxury builds. These precision fabrication for Utah projects meet stringent standards, providing reliability for homeowners and contractors alike.

This guide delves deeper into the benefits, processes, and best practices of metal fabrication. Whether upgrading a high-end residence or outfitting a commercial space, discover how Viotell can elevate your project. Request a quote today to explore custom solutions suited to your Utah vision.

What is Custom Metal Fabrication

Custom metal fabrication involves the precise creation of metal components tailored to specific project requirements, particularly in Utah’s demanding architectural landscape. For companies like Viotell in Salt Lake City, this process ensures high-quality outputs that meet local building codes and environmental challenges. By combining advanced techniques with durable materials, fabricators deliver solutions for luxury residential and commercial projects, from roofing systems to structural elements.

Defining Custom Metal Fabrication Processes

Custom metal fabrication in Utah begins with detailed design and proceeds through several key stages to produce unique components. This bespoke metal crafting in Utah emphasizes precision to meet client specifications for architectural needs. The process starts with material selection, often using robust steel grades like A36 for general structural integrity or weathering steel for corrosion resistance in Utah’s variable climate.

- Cutting: Laser cutting provides accurate shapes with minimal waste, achieving up to 99% material efficiency as noted in standard steel fabrication practices.

- Forming: CNC bending shapes metal sheets into curves and angles using computer-controlled machines for consistency.

- Welding and Assembly: Skilled welders join pieces with techniques like MIG or TIG, ensuring strong bonds that withstand Utah’s harsh winters and summers.

- Finishing: Surface treatments such as powder coating protect against rust and enhance aesthetics.

Applications in Roofing and Architectural Work

In roofing and architectural projects, custom fabrication supports durable and visually striking features tailored to Utah’s luxury builds. Sheet metal fabrication in Utah produces essential elements like standing seam roofing panels that offer superior weather resistance and longevity. These panels, often made from galvanized steel, channel snow melt effectively in Salt Lake City’s snowy conditions, reducing ice dam risks.

- Roofing Panels and Flashing: Custom-cut pieces ensure watertight seals around edges and valleys.

- Chimney Caps and Wall Systems: Fabricated to fit unique rooflines, enhancing both function and style.

- Ornamental Elements: Ornamental metal work Utah adds decorative flair, such as railings or accents, blending artistry with structural support.

Differentiating from Standard Manufacturing

Unlike standard manufacturing, which focuses on high-volume, identical products, custom metal fabrication prioritizes individualized designs adapted to specific needs, especially in Utah’s climate-adaptive projects. Mass production relies on assembly lines for uniformity, while bespoke processes allow for variations like reinforced edges on roofing to handle high winds or UV exposure common in the region.

Benefits of Custom Metal Fabrication in Utah

Custom metal fabrication in Utah offers transformative advantages for architectural projects, particularly in roofing and paneling. Viotell Metal Concepts leads the way with precision craftsmanship tailored to local needs, ensuring structures withstand the region’s unique demands while enhancing visual appeal and financial returns.

Durability and Longevity for Utah Climates

Utah’s diverse climate, featuring heavy snowfall in the mountains and intense summer sun in the valleys, demands robust materials. Custom metal fabrication in Utah employs local steel grades engineered for extreme conditions, providing superior weather resistance.

Icons showcasing durability, aesthetics, and cost savings of custom metal roofing fabrication.

Cost-Effectiveness Over Time

While initial investments in metal fabrication in Utah may seem higher, the long-term economics prove compelling. Low-maintenance designs reduce repair needs, and energy-efficient properties lower utility bills, especially in climate-controlled Utah environments.

How Custom Metal Fabrication Works

Custom metal fabrication transforms raw materials into precise architectural components, particularly for metal roofing systems in Utah. At Viotell Metal Concepts, this process ensures durability and aesthetic appeal tailored to Salt Lake City’s unique climate.

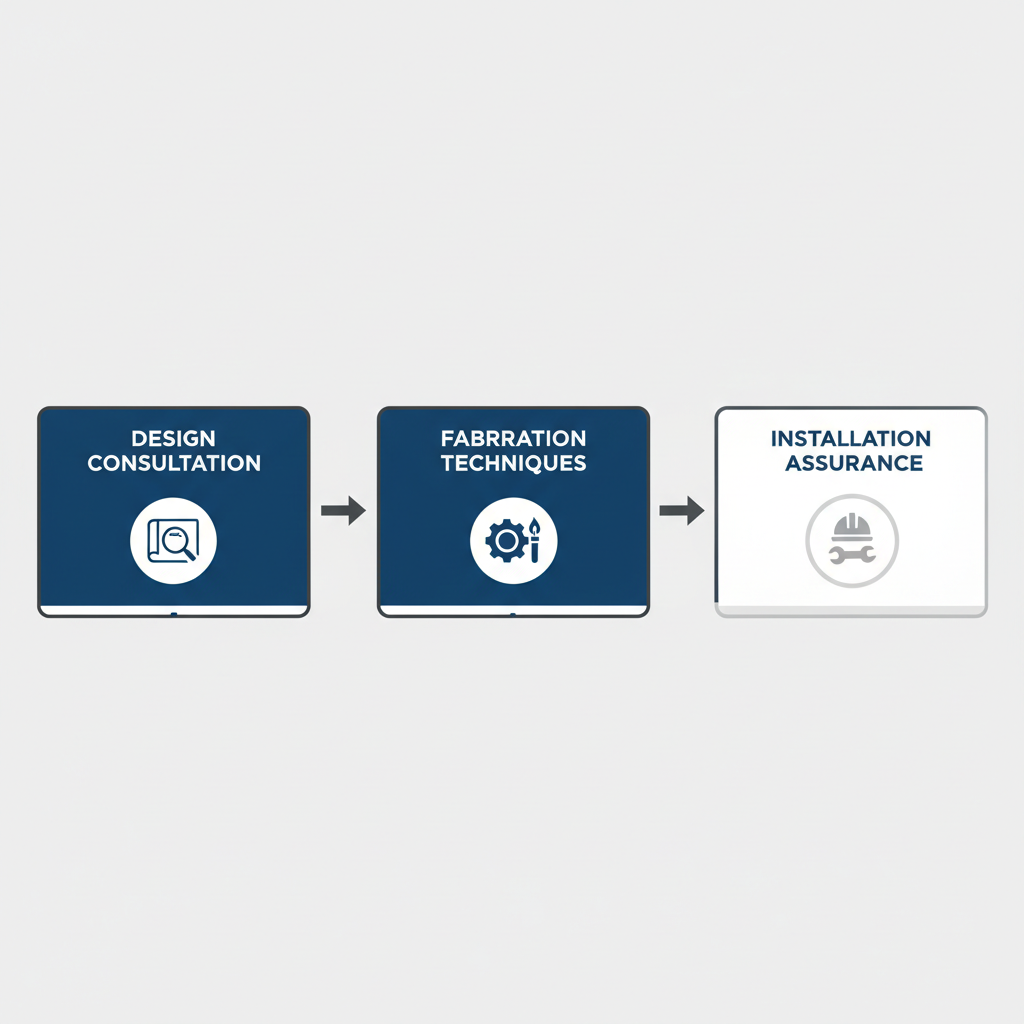

Step-by-step guide to Viotell’s custom metal fabrication process

Best Practices for Custom Metal Fabrication Projects

Undertaking custom metal fabrication in Utah requires strategic approaches to ensure durability and efficiency. By focusing on reliable partners, thorough planning, and proactive maintenance, projects can withstand the region’s unique environmental challenges.

Choosing the Right Custom Metal Fabrication Partner in Utah

Navigating the world of custom metal fabrication in Utah requires understanding the core processes, from design and cutting to welding and finishing. Key takeaways include partnering with firms offering robust warranties and local expertise to mitigate risks and enhance project outcomes. Viotell exemplifies this approach, delivering specialized metal roofing solutions with a focus on craftsmanship across Utah markets.